Our safety shoe factory established in 2001, with professional cementatory, good-year welt and injection production line which can produce professional safety shoes with cementatory construction, cementatory and side stitching construction, good-year welt construction, injection construction. Always with high quality self-requirement, continuous improvement and evolution, starting from the brand spirit of safety, comfort, ventilation and light weight, according to the market research and development of new safety shoes to meet the needs of the economy and society.

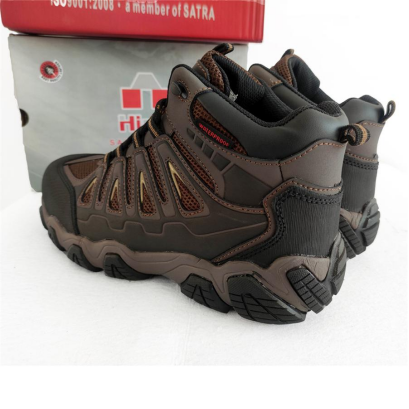

Name: Sportive style waterproof safety shoes with cementing sole

Style no.: TK-V6 / TK-V9

The design is sporty, fashionable, lightweight and waterproof. These shoes can keep your feet dry in a watery workplace.

Upper part is made of microfiber and sandwich materials. Microfiber is water repellent and good water absorption. Sandwich mesh soft, comfortable and ventilation. And the original Hot-Print design make the shoes more fashionable.

We use waterproof, breathable and scratch-resistant inner sock to make the shoes water resistance to the test EN ISO 20344:2011, 5.15.2 , attains CE certificate standard WR.

All the insoles are BK trilex+moulded PU insole, surface BK trilex which is abrasion resistance, and PU part is comfortable and shock absorption.

EVA+Rubber cementing outsole, EVA midsole part is soft, light weight and shock absorption. Rubber outsole is oil resistance, abrasion resistance, weak acid & weak alkali resistance, insulative, heat insulation, high anti-skidding attains CE SRC the highest slip resistance standard, can meet a variety of workplace protection needs.

With CE composite toe cap, make the shoes more light on the basis of impact resistance & compression resistance. Insulation makes shoes more widely used, especially suitable for electric power plants and other electric work places to wear.

During the mass production process, in addition to the regular materials test, our factory will especially pay more attention on the waterproof test on this shoe.

Before stitching production line, we have a special instruments could test the workproof sock materials firstly, to Eliminate unqualified waterproof socks in time. After finishing the shoes, we use advanced waterproof testing instrument SATRA TM77 to test the waterproof of the whole footwear again. During the test, the test water level in the instrument is 20mm, the instrument will bend the shoes 22±5 degrees, the bending speed is 60±6 times per minute, continuous bending 80 minutes, no water penetration in the shoes after the bending is passed the test.

Other details:

Color: as the pictures or other as customers require

Size: EUR 36-46

MOQ: 500prs as the pictures color, 1000prs as other color of customers require

Packing: shoes box / master cartons

Payments terms: TT, 30% deposit in advance, other balance against BL copy

Port: QINGDAO of China

In addition to passing various safety test certifications, every safety shoes style of our factory is designed for ergonomics. With a variety of designs we make shoes safe, comfortable and aesthetic. So safety shoes are no longer just for working needs, they are also new fashion trend.

Post time: Jun-30-2022